We are focusing on forward thinking in redefining and advancing the technology in the rubber sector in Malaysia

Putting heat and pressure together helps to make the rubber into the shape you want. A heated mold tool and the pressure of a press are used to make the rubber into the shape you want.

Molding Machine

The rubber cutting machine is basically designed to slit and cut very dense rubber compound sheets into the desired dimension for the compression molding machine.

Rubber Cutting Machine

Post curing oven is used in the "after cure" process of exposing the rubber parts or mold to an elevated temperature to speed up the curing process, fix the rubber into its final shape, and maximize some of the material's physical properties.

Post Curing oven

A precision balance or precision scale is used to indicate a better grade of balance or weighing scale with high precision (up to 0.01g readability).

Precision Weighing Scale

The ultra-shot machine makes use of the cooling of liquid nitrogen to make the flashes of molded components brittle and blast shot media at high speed to de-flash the rubber components.

Ultra-shot Machine

It is used to effectively clean the stainless steel compression mold from all sorts of contaminants and dirt even are hard to be reached the surface without damaging the dimensional integrity and the surface of the mold.

Mold Cleaning Machine

A rubber rheometer is used to test and determine the raw rubber flow in response to applied force in our laboratory. It is designed to use on fluids that cannot be defined by a single value of viscosity.

Rheometer

A high elongation extensometer is used to define the extent (in %) of rubber material that can be strained before it breaks or deformed permanently.

Elongation Tester

The Shore durometer is used to measure the hardness of materials like rubbers typically with a Shore A scale system. It is to determine the resistance of rubber material has to indentation to meet the performance and quality of industrial specifications.

Hardness Tester

The Tool Maker's microscope is used to measure the size, angle, shape, and position of a rubber component with high accuracy to fulfill the requirement of rubber component to be used for high precision applications.

Tool Maker's Microscope

The profile projector is used to do the linear measurement of rubber components on a magnified scale for better and easier calculation.

Profile Projector

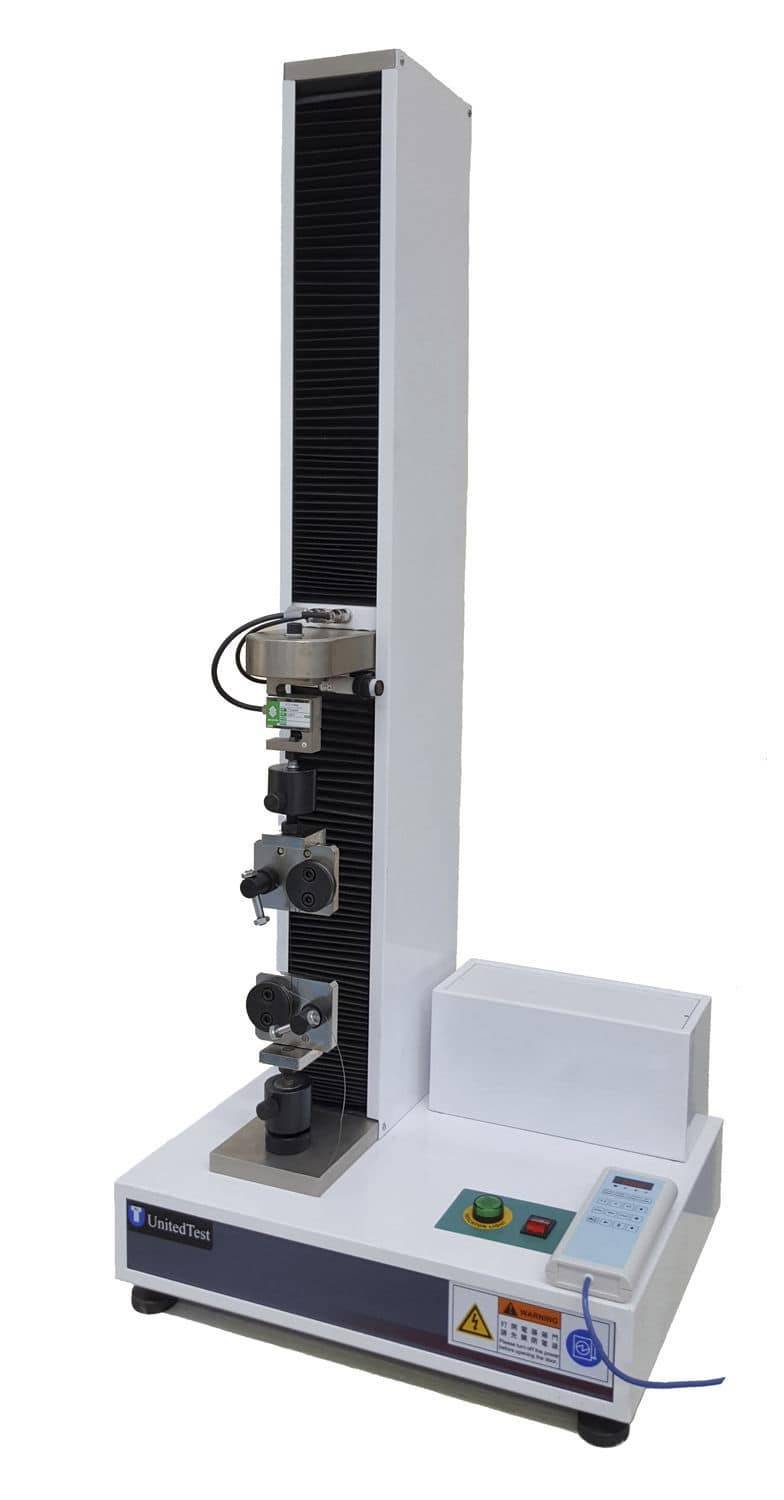

The load force tester is designed to make basic force measurements where the peak load and extension are the main interest or requirement to determine the physical load properties of a given rubber component.

Load Force Tester

Nitrile rubber (NBR), Styrene-Butadiene rubber (SBR), Natural rubber (NR), Ethylene-Propylene Terpolymer Rubber (EPT), Ethylene-Propylene-Diene-Monomer rubber (EDPM), Chloroprene rubber (CR), Butyl rubber, VITON rubber and Silicone rubber are some of the base-material we use for our rubber compound. Our products has been used in various industry applications in Malaysia including audio, video, telecommunication, printing, computing, electronic and so on.

Vulcanized rubber’s physical and chemical qualities can be determined, in part, by the rubber mixing process (RMP). Rubber mastication is the first step in the RMP process, which is followed by the addition of rubber chemicals and/or filler. Three stages of rubber compounding were carried out on a two-roll mill. In the first stage, the rubber was combined with numerous additives and chemicals. To finish up the rubber compound, we used a rubber masterbatch.

Compression molding is a tried-and-true method of making simple rubber items. The method is comparable to waffle-making – a specified amount of uncured rubber is poured into a mold cavity, which is then closed and heated. When the components have cured, they are taken from the mold.

The 2-roll rubber mill is a machine (kneader & milling machine) used to transform rubber into various compounds. 2 horizontally opposed stainless steel rolls rotate in opposite directions towards each other at varying speeds to mix the rubber and materials necessary to manufacture rubber compounds.

Mixing Machine